Emulsifiers in Poultry Feed: How They Impact Efficient Energy Utilisation

The poultry sector in India is valued at about Rs 80,000 crore (2017-2018) mainly divided into two sub-sectors- one with a highly organised commercial sector with about 80% of the total market share, say Rs 60,000 crore. The unorganised sub-sector with about 20% of the total market share of Rs 16,000 crore respectively.

Amidst rising feed prices, scientists are exploring innovative strategies to reduce costs without compromising animal health. Young animals face challenges in fat absorption due to low natural lipase and bile salt production, contributing to increased energy demands and escalating feed prices. Emulsifiers in poultry feed play a crucial role in enhancing fat digestion and absorption. By stabilising and dispersing fat globules, an emulsifier in poultry feed promotes a uniform mixture in the feed, improving nutrient utilization and potentially reducing the need for excessive energy sources.

This blog by Glamac takes a deep dive into the role of emulsifiers in poultry feed and how they impact energy-efficient utilization.

What Are Emulsifiers in Poultry Feed?

A recent approach gaining attention among nutritionists for achieving efficient energy utilisation involves the utilisation of exogenous surfactants, commonly referred to as “emulsifiers,” which can be effectively broken down by lipase. Emulsifiers in poultry feed play a crucial role in stabilising mixtures of substances that do not naturally blend well, such as oil and water.

They prevent the coalescence of globules in the dispersed phase, necessitating the initial emulsification of lipids. This process results in the formation of small, emulsified fat droplets, expanding the contact area for lipase enzymes produced by the pancreas. The natural or synthetic emulsifier in poultry nutrition is employed to enhance fat digestibility, thereby promoting energy efficiency and ultimately mitigating feed costs.

Importance Of Emulsifier In Poultry Feed

Comprising a hydrophilic head and a hydrophobic tail, emulsifiers in the poultry industry have distinct orientations: the hydrophobic tail faces the oil phase, while the hydrophilic head points towards the watery phase. The lipophilic part is composed of fatty acids derived from fats and oils like soybean oil, rapeseed oil, coconut oil, and palm kernel oils. In contrast, the hydrophilic portion can consist of substances such as sucrose, propylene glycol, glycerol, sorbitol, or polyglycerol.

Guided by the hydrophilic-lipophilic balance principle, a specific emulsion type is systematically chosen, and the proper combination of emulsifiers in poultry nutrition enhances stability. The role of any emulsifier in poultry feed is to reach the protein-stabilised interface by navigating through small openings in the interwoven protein layer.

Commercial Emulsifiers In the Poultry Feed Industry

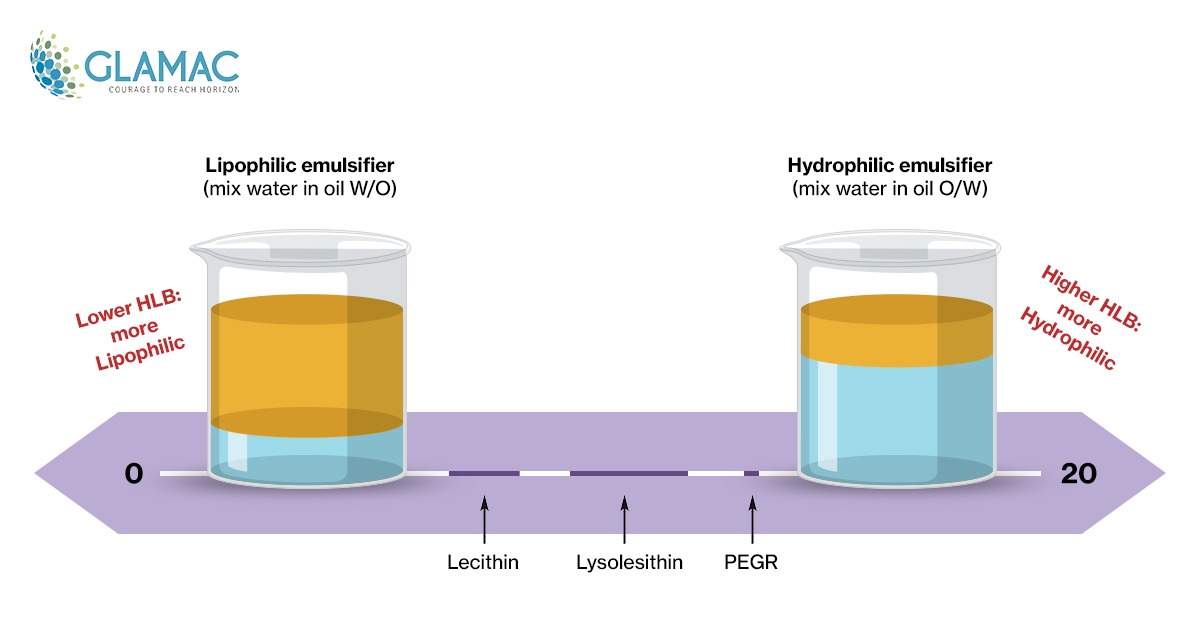

1. Lecithin (Phospholipids):

- Characterized by being a more lipophilic emulsifier.

- Possesses a low HLB value.

- Not suitable for poultry use due to its structure containing two lipophilic tails and one hydrophilic head.

2. Lysolecithin (Lysophospholipid):

- Functions as a hydrophilic emulsifier.

- Exhibits O/W emulsifying properties.

- Despite its effectiveness, its HLB falls below 13.

- Derived from lecithin and has one lipophilic tail and one hydrophilic head.

3. GPEGR (Glyceryl Polyethylene Glycol Ricinoleate) / PEGR (Polyethylene Glycol Ricinoleate):

- Classified as a hydrophilic emulsifier.

- Demonstrates O/W emulsifying properties.

- Possesses an HLB value of around 13.10 and above.

- Derived from castor oil, it features a structure with a more hydrophilic portion.

- Castor oil, rich in long-chain unsaturated fatty acids, serves as a potent emulsifier.

- Any potential toxicity from the ricin enzyme is eliminated through heat treatment.

What is The HLB value Of An Emulsifier?

The HLB value of an emulsifier is a measure of the balance between its hydrophilic and hydrophobic (lipophilic) components. This value plays a crucial role in determining the emulsifier’s selection and effectiveness. Essentially, HLB provides a numeric representation of how well a product can dissolve in fat or water. The HLB scale ranges from 0 to 20, with lower values indicating a higher affinity for fats and greater lipophilicity. Conversely, higher HLB values signify a stronger attraction to water and increased hydrophilicity in the emulsifier.

Functions Of Emulsifiers in Poultry Feed: Enhancing Energy Efficiency

Emulsifiers in poultry nutrition play a vital role in enhancing the digestion and absorption of lipids, contributing significantly to the overall efficiency of poultry feed. In the context of the poultry industry, understanding the role of emulsifiers in poultry feed formulations is crucial for optimising nutrient utilisation and promoting cost-effective production. Here are some points that showcase how emulsifier in the poultry feed industry is vital :

Functions Of Emulsifier In Enhancing Energy Efficiency Of Poultry – #1

- Improved Digestibility of Fats:

Emulsifiers in poultry feed enhance the breakdown of dietary fats into smaller droplets, increasing the surface area for enzymatic action. This improved fat digestion leads to better absorption of fatty acids, which serve as a concentrated and valuable energy source for poultry.

Functions Of Emulsifier In Enhancing Energy Efficiency Of Poultry – #2

- Enhanced Nutrient Absorption:

By facilitating the emulsification of fats, Poultry feed emulsifiers contribute to the overall efficiency of nutrient absorption in the digestive tract. This is critical for the assimilation of essential fatty acids and fat-soluble vitamins, which are important for energy metabolism and various physiological functions in poultry.

Functions Of Emulsifier In Enhancing Energy Efficiency Of Poultry – #3

- Energy Availability for Growth and Production:

Efficient energy utilisation directly correlates with the bird’s ability to convert nutrients into energy for growth, egg production, and maintenance functions. Emulsifier in poultry feed industry plays a role in optimising energy availability, ensuring that the birds receive the maximum benefit from the feed they consume.

Functions Of Emulsifier In Enhancing Energy Efficiency Of Poultry – #4

- Reduction in Feed Wastage:

Emulsifiers in the poultry feed industry can help reduce feed wastage by promoting the uniform distribution of fats in feed formulations. When fats are effectively emulsified, it minimises the likelihood of fat separation and improves the overall palatability of the feed, encouraging birds to consume the entire ration.

Conclusion

In conclusion, the incorporation of emulsifiers in poultry feed positively influences energy utilisation by improving the digestibility, absorption, and stability of key nutrients. This not only enhances the overall efficiency of energy conversion but also contributes to the well-being and performance of poultry in commercial production systems.

Liptivo XT, a distinctive nutritional emulsifier developed by Glamac, distinguishes itself from conventional emulsifiers. Its German origin ensures the highest standards of quality and effectiveness. The formulation is a combination of highly concentrated Lysophosphatidylcholine (LPC) and Glyceryl polyethylene Glycol Ricinolate (PEGR), both carrying elevated HLB values. With its exceptional HLB value, Liptivo XT excels in emulsifying various types of fats, establishing itself as an invaluable tool in poultry nutrition.